We have become accustomed to seeing robots in the workplace in big industries like auto manufacturing, but most Americans work in smaller companies, so the threat of smart machine replacement for those jobs is not so great, right? Wrong.

It’s disconcerting that Washington is snoozing through this fundamental transformation of the employment universe where the human worker is becoming obsolete in the production of goods and services. The CEO of the Gallup pollsters remarked a few months back that “At the recession, we lost 13 million jobs, only three million have come back,” which is sounds like a good snapshot of the American economy: jobs are not being created and the cause is partially smart machines.

There’s not a lot that can be done by government to deal with technological change, but political leaders should at least jettison the delusion of a future worker shortage caused by the retirement of millions of boomers: many of those jobs will be done by smart machines.

Therefore, the correct number of immigrant workers is ZERO. The technological revolution in the workplace making humans less necessary means any new low-skilled immigrants (which is most of them) will end up in the welfare office. Instead of importing superfluous immigrants by the millions, the government must focus on citizen needs. In particular, schools should partner with business to include training that prepares American young people for the few jobs that remain.

The latest small-business productivity tool: The robot, CNBC, May 2, 2015

47% of US jobs at high risk for being automated in 10 to 20 years

Robots arent just for corporate Goliaths; even the little guy on Main Street is adopting them. Their goal: to boost sales and productivity. But at what cost?

Take Sam Kraus, a Hungarian immigrant who founded what became Skyline Windows in 1921. In the early days, the tinsmith traveled around with a small cart to do his roofing and waterproofing work by hand.

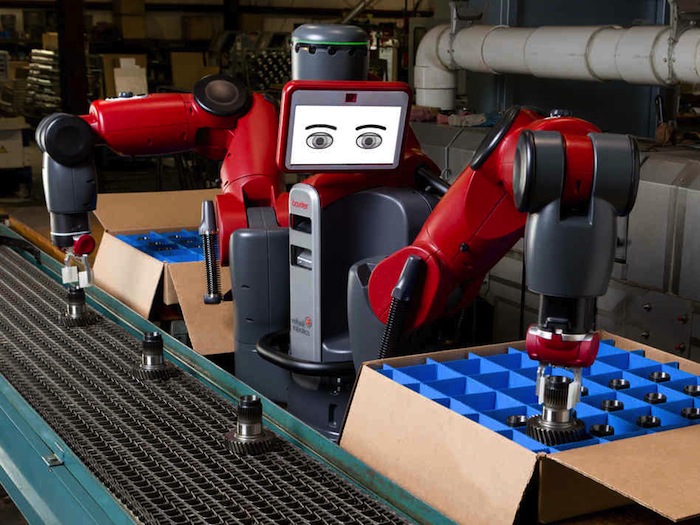

Fast-forward to today, and the fourth-generation business, based in New York Citys South Bronx, has left the pushcart era far behind. Skyline, which has evolved into a custom window manufacturer and installer, now relies on robots to do some of its work. In the factory in Woodridge, New Jersey, where it makes its windows, Skyline uses a $150,000 computer-operated machine to automate tasks like cutting holes in the metal and two $20,000 robots to install its windows, which sometimes weigh 600 pounds.

It allows us to be more efficient—and our plan is to buy more of these robots when we can, said senior vice president Matt Kraus, whose profitable firm brings in about $70 million in annual revenue and employs about 350 people.

Kraus is one of many entrepreneurs who are discovering that robots can be a powerful tool for growing a small company—even one with its roots in an old-line business. In the manufacturing industry, a recent study by Boston Consulting Group found that by 2025, robots will do about 25 percent of all industrial tasks—and that inexpensive robots are becoming increasingly available to smaller companies. Robotics are also making it possible for more individuals to start businesses in industries where the need for a substantial labor force once posed a big barrier to entry.

Automation is having a big impact, said Martin Ford, author of Rise of the Robots: Technology and the Threat of a Jobless Future, due to be published May 5. Its both positive and negative.

3D printing is one example. Some tiny firms are already using 3D printers to make prototypes and even manufacturing products on their own, as Ford notes. Others are sending the prototypes to China, where they make the products. That will make it easier for entrepreneurs to build wealth, but the flip side will be a decline in traditional jobs.

The future of jobs

Businesses will need to hire no people or fewer people, he said. You can literally have one person start a manufacturing business.

A decline in traditional jobs could lead to shrinking markets for small businesses, said Ford. We need consumers out there who will buy what is created by the economy, he explained.

Automation may also make some small businesses obsolete—just as online booking dealt a fatal blow to many travel agencies. Forty-seven percent of total U.S. employment is in the high risk category of being automated within the next 10 to 20 years, according to research done at University of Oxford by Carl Benedikt Frey and Michael Osborne, co-directors of the Oxford Martin Programme on Technology and Employment.

Among the 702 occupations they studied, telemarketing was at the highest risk of automation, followed by title examiners, abstractors and searchers. The work least likely to be automated, according to the research, was recreational therapy.

The small businesses with the greatest long-term chances of survival perform tasks that require social intelligence, creativity and the perception and dexterity to react to a quick-changing environment, Osborne said. To the extent a small business is heavily concentrated toward those activities, it probably is not going to be automatable, he added.

But a clear picture of how automation and robots will affect small and midsize firms and their employees is still emerging. At Skyline Windows, using robots has led to at least one new job, said Kraus. The company had to hire and train someone to operate the new machine that has automated aluminum processing at its plant.

Automations multiplier effect

Meanwhile, when the company uses a robot to install windows, it still needs one worker on site to run it using what looks like a video game console and the other to help position the window by hand. The three or so workers who are no longer needed to hoist the windows do other tasks.

If we free up three guys, we have those three guys working on something else, Kraus said. Its not like were saying we need three less guys and are going to lay those guys off.

Meanwhile, many young entrepreneurs are creating new businesses that tap the power of robotics and automation.

Hoovy, based in Los Angeles, is an advertising platform that uses drones to raise brand awareness. Founder Eugene Stark said these drones are like flying billboards. The 10-person business, which makes the drones in its headquarters, charges between $120 and $200 an hour for the advertising, depending on whether it is done on a weekday or weekend. Stark said it has used the drones to promote such things as the Glendora Wine Walk, an event where local merchants serve California wines, to a barber shop. In one hour, three people booked appointments, he said.

To make sure the public is safe, Hoovy places tents under the drones and has designed them so the drones descend if the batteries start dying, he said. The company also abides by FAA guidelines recommending that licensed pilots operate the drones, which means paying a pro up to $40 an hour to be on site during promotions, he explained, adding that the company, which is turning a profit, is planning a campaign on crowdfunding site Kickstarter at the end of April.

Were seeing a lot of traction, he said.

Another new player is Eight Six Ninety-One Technologies. Avoiding the word drones because it evokes security concerns, the Chicago start-up, founded last fall by Jackie Wu, Ritwik Ummalaneni and Florent DSouza, has developed a flying indoor security camera using a craft it calls quad copters. The technology can also be used to monitor babies and pets, Wu said.

We can fly over to where Fido or Fluffy is when youre at work, explained Wu, a former consultant in the pharmaceutical industry. You can pull out your phone, talk to them and say hi.

They plan to sell access to the product via a software-as-a-service model, where consumers will pay a recurring fee to use the technology. Were still in the early stages, said Wu.